Welcome to Our Company -

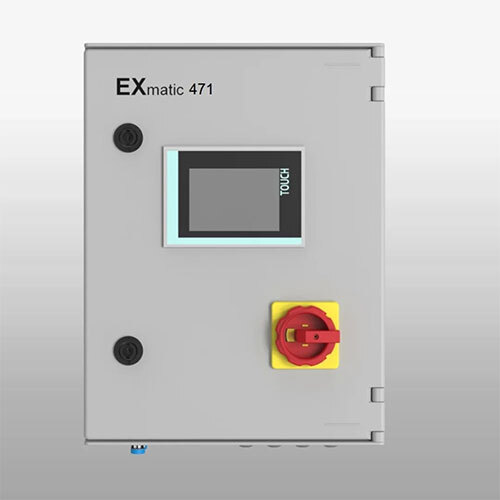

EXmatic 470

Product Details:

- Current Range 4-20 mA

- Sensor Type Load Cell

- Resolution 1 kg

- Frequency 50 Hz

- Measurement Range 0-9999 kg

- Humidity % <90% RH Non-Condensing

- Connectivity Type Relay Output, RS232/RS485 (Optional)

X

EXmatic 470 Product Specifications

- 0C to 55C

- 7 Segment LED Display

- 10 VA

- ABS Plastic Cabinet

- 1 kg

- Load Cell

- 0-9999

- 50 Hz

- Relay Output, RS232/RS485 (Optional)

- 0.5% F.S.

- <90% RH Non-Condensing

- 0-9999 kg

- 230V AC, 50 Hz

- 4-20 mA

- Up to 9999 kg

Product Description

Advantage

- Full automatic measuring point

- High extension of sensor-lifetime and reducing of servicing efforts

- Open system operates with any kind of transmitter

- Output signals for connecting with PCS

- Three different cleaning solutions usable

- Sealing water function

- Pre- and post-cleaning function

- Integrated connecting hose for plug and play operation

- Safe removal of the sensor under current process conditions

Precision and Efficiency for Your Packaging Needs

With its fully automatic operation, the EXmatic 470 streamlines the cartoning process, delivering high throughput, precise handling, and reliable sealing. Designed to maximize productivity, the machine offers easy adjustment for carton sizes and quick changeovers, making it ideal for businesses requiring flexibility and speed.

Versatile Control and Monitoring

Equipped with a PLC-controlled system and a large 7-segment LED display, operators can easily monitor and manage production data. Its connectivity features, including relay outputs and optional RS232/RS485 interfaces, allow seamless integration into modern packaging lines.

FAQs of EXmatic 470:

Q: How does the EXmatic 470 operate and what control system does it use?

A: The EXmatic 470 operates fully automatically using a PLC-controlled system. This allows for efficient and precise handling of packaging tasks, minimizing manual intervention and enhancing reliability.Q: What is the recommended process for changing carton sizes on the EXmatic 470?

A: Carton size adjustments on the EXmatic 470 can be completed within 15 minutes. The process involves minor mechanical adjustments and setting parameters via the LED display, making it efficient for frequent product changeovers.Q: When is the ideal time to perform maintenance on the EXmatic 470?

A: Routine maintenance should be performed according to the usage intensity and manufacturers guidelines. Normally, regular inspections and cleaning are recommended during scheduled downtimes to ensure sustained performance and longevity.Q: Where can the EXmatic 470 be installed for optimal results?

A: The machine is suitable for use in industrial packaging environments across India, ideally in areas with controlled temperature (0C to 55C) and humidity levels below 90% RH, ensuring optimal operation and durability.Q: What benefits does the EXmatic 470 offer to distributors and service providers?

A: Distributors and service providers benefit from its robust construction, high accuracy, quick changeover, and versatile sealing options. These features support diverse packaging applications, ensuring efficiency and adaptability to various client needs.Q: How energy efficient is the EXmatic 470?

A: The EXmatic 470 runs on 230V AC, 50 Hz power supply, consuming only 10 VA, making it energy-efficient and suitable for continuous operation.Q: What carton sealing options are available on the EXmatic 470 and how are they selected?

A: The machine offers both tuck-in and hot melt glue sealing options. The preferred sealing method can be selected based on product requirements and adjusted quickly during changeover, providing flexibility for different packaging needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free